About company «INSTA»

LLC “INSTA” – a company specializing in development and batch production of composite high-voltage insulators and the isolating structures for HV lines and substations.

The head office of LLC “INSTA”, marketing services and one of warehouses are located in Moscow. The manufacture is situated in Lysva city, Perm Region. INSTA has begun the production of modern composite insulators for HV lines and substations in 2005. Development of insulator’s design and the production technology is carried out with active participation of the leading branch organization - LLC “Special Technological Construction Bureau for Insulators and Fittings” .

Nowadays, LLC “INSTA” is one of the top three Russian producers of composite insulators. During their 13 years of existence more than 2 million 400 thousand composite insulators of different voltage levels and mechanical durability has been made and put into operation. Production of LLC “INSTA” is successfully applied on power facilities in Kazakhstan, Kyrgyzstan, Uzbekistan, Moldova, Belarus, Turkmenistan and Georgia.

Since 2009 LLC “INSTA” is a part of a huge Russian industry group “FORENERGO”.

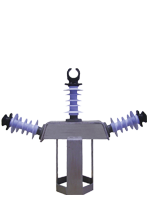

Production

We use only modern technological equipment for the production of composite insulators.

There are six injection automatic presses located on the territory of industrial complex. They are capable to produce over 50 thousand composite insulators monthly. Also, six transfer molding presses produce over 20 thousand products per month.

The press molding shop of end-fittings is equipped with five radial press units with ultrasonic control of the quality. There are three stands of press molding of the flanges for post composite insulators. The modern technological line is used for production of compounded rubber.

The modern insulator design and high-automated processing equipment almost completely exclude influence of subjective factors on quality of the insulators, which have stable high level of quality output.